Providing turnkey projects for plants has become part of our challenges in a natural way

What does it consist of?

Advantages

Cost reduction must be based on choosing a company capable of carrying out a turnkey project efficiently. This materializes the selection of a winning proposal for the client, with a quick return on investment.

TECNIMIL offers its clients the enormous advantage of dealing with a single integrating company, with which any and all problems relating to the project can be assessed and studied, in order to guarantee the efficiency for which we stand, from the construction of foundations to the delivery of finished products.

Optimum use of time translates into reduced delivery times. Tecnimil accomplishes this task by first carefully scheduling all activities related to work orders and then closely monitoring their implementation, thus guaranteeing contract deadlines. This method guarantees trouble-free operation and, consequently, no loss of time during the execution of civil works or the installation of electromechanical equipment.

Stages of

development

General

Layout

Preliminary

Design

Sheet

flows

Building

design

Purchase

Manufacturing

Automation

systems

Layout

design

Installation

sites and

layout

Mobilization and

management of the

factory site

Shipping

and goods

Civil work and

electromechanical

installation

Commissioning

of the plant

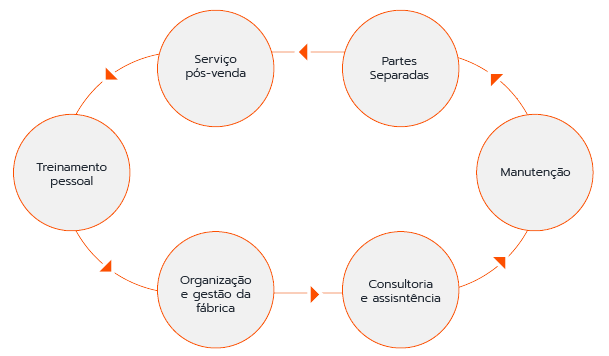

Services

Auxiliary installations

facilities

Mobilization and Work Management